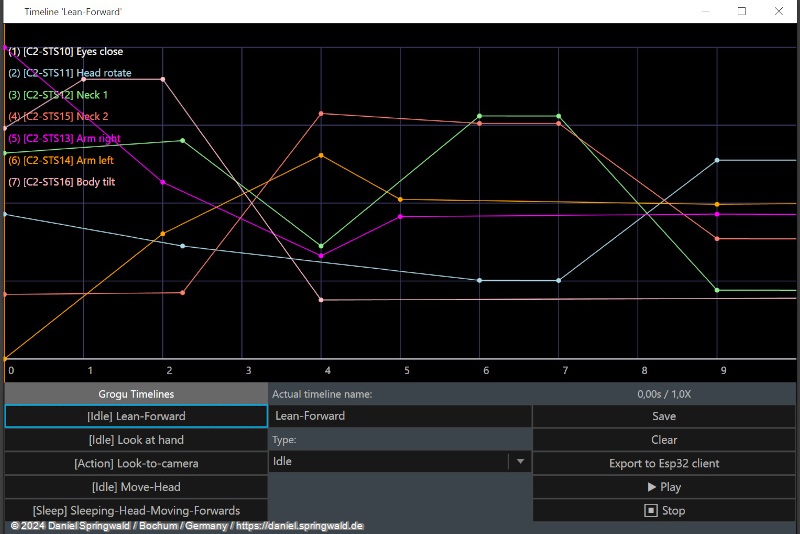

Animatronic Grogu 2.0

This is the first part of a small series of articles about building an improved version of the animatronic Grogu.

Important note

I didn't use the process described here for the final construction of Grogu. I have summarized the new experiences with two-piece silicone molds in a separate article: Multi-Piece Silicone Molds for Animatronic Dolls

3D printing as a basis

In order to make the head shape of Grogu as authentic as possible, I bought a pretty faithful 3D model of Grogu. I had to divide this into several parts so that they did not exceed the build volume of my 3D printer. On the other hand, I wanted to print the ears separately in order to be able to make them more mobile later.

Mold making with silicone

I have been interested in silicone mold making for many years, but I have never dared to do it before. Instead of the entire head, I wanted to build up only the face as a test in order to gain some experience there.

Since almost nothing adheres to silicone (not even acrylic paint by airbrush), several specimens of the face could be used for experiments. I also wanted to build the mechanics for the eyes and mouth only in isolation for the face and thus test possible variants before I ventured onto the entire head.

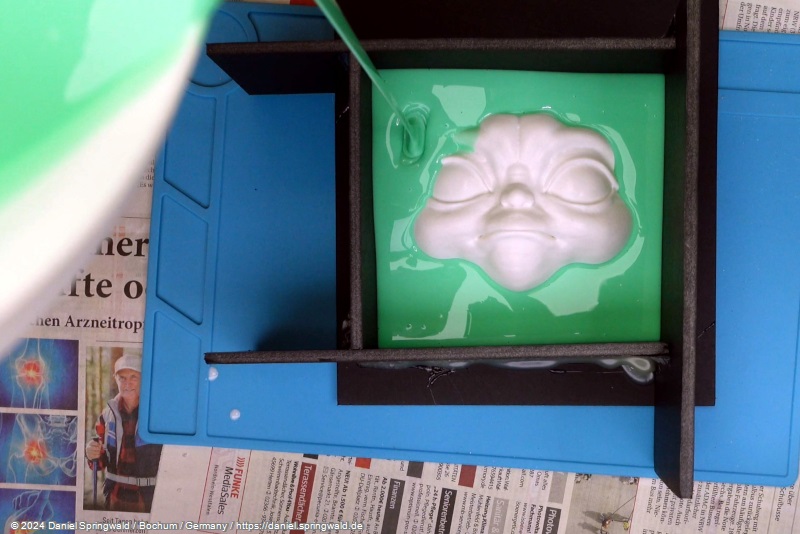

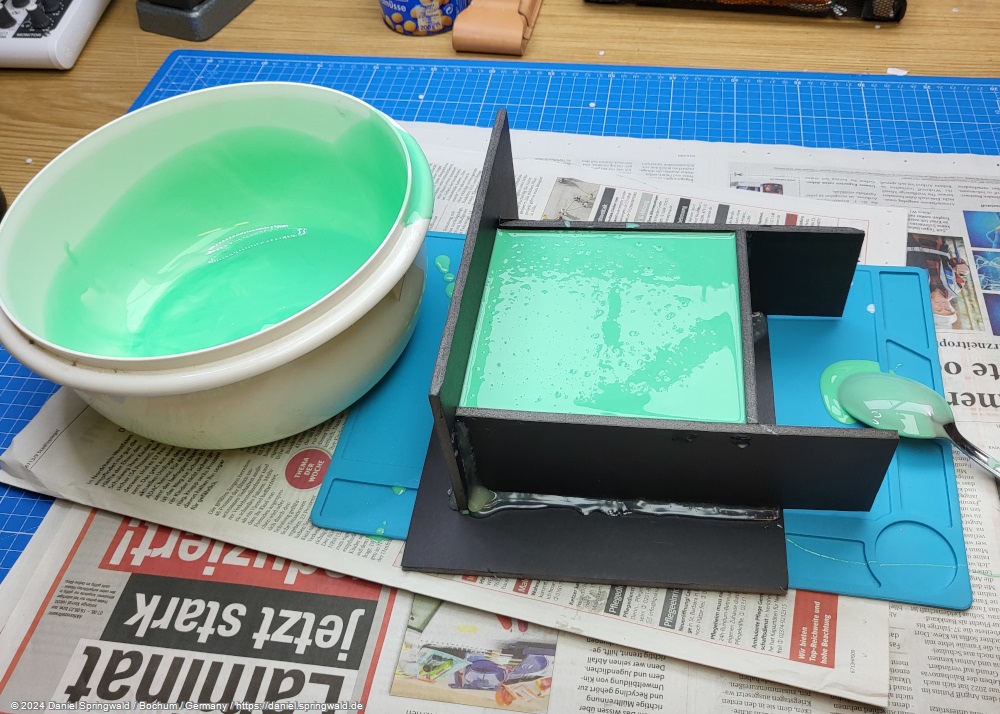

Later, in order to cast the face from silicone, it is first necessary to make a mold - also from silicone. To do this, I used the "Type 1 duplicating silicone soft" from Troll Factory . This is a 2-component silicone that is mixed in a 1:1 ratio. This worked surprisingly well on the first try: Simply build a small box of reinforced cardboard around the face and pour it out.

The cardboard form box is glued together with hot glue and sealed with it:

The silicone is then poured into the box and has to harden there. This takes several hours, depending on the silicone used.

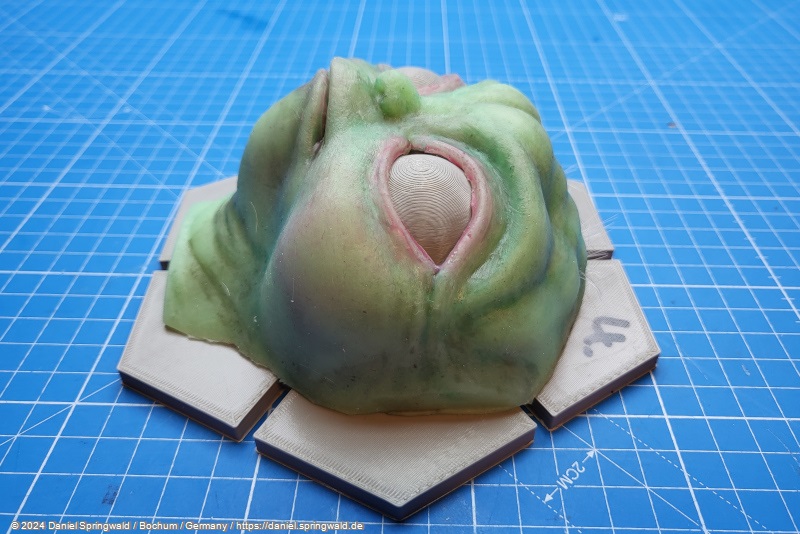

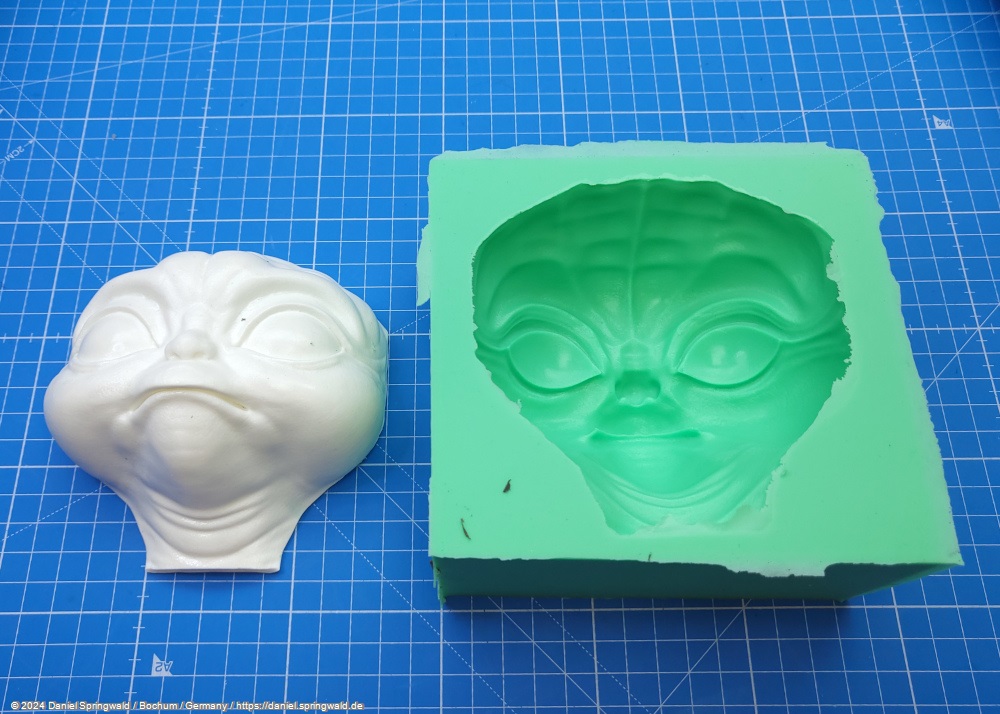

After the silicone has hardened, you can remove the cardboard box and remove the face from the silicone mold:

Silicone face casting

After the mold was ready, I was able to cast the face from silicone. For initial tests, I used the same duplicating silicone as for the mold.

So that silicone is not poured on silicone (and glued at the end), the mold must be treated with a release agent beforehand. I used Oputec mold release spray for this, which worked very well. In addition / alternatively, talc can probably also be used to treat the mold with it or to make it more storable.

In contrast to the usual pouring with resin or silicone, however, this should not be a massive object, but a thin silicone skin.

Similar to the production of chocolate Santa Clauses, the mold is therefore only poured with a small amount of material and then swirled until the mold is completely lined with silicone. However, this would have to be done all the time until the silicone is roughly cross-linked (= cured). Because this takes a few minutes, some hobbyists build a swivel device for this purpose, which automatically swivels the shape. That was actually my plan, but it seemed rather unattractive to me: The machine would probably take up a lot of space in the end due to its two axles and motors and would have to be built first. While pondering how I could best solve this, I came up with the saving idea: This would be the ideal job for my robot arm!

The robot swivels the silicone mold during curing:

First results

The face also worked quite well right from the first try. There are no holes caused by bubbles in the silicone and the details are also quite easy to see:

The silicone has spread well when swivelling and completely lined the mold. However, I probably used a little too much silicone with 80ml, as the skin is quite thick in some places.

The next attempt was therefore with 60ml silicone. The swivel with the robot arm also worked well here, the silicone was evenly distributed in the mold.

Now most of the silicone accumulated in the small bulges of the model (as if above the eyes). This is understandable, because the material flow inside probably wants to achieve a surface that is as smooth as possible.

Unfortunately, this means that between the bulges, the material is very thin, transparent and tends to crack.

So a little more silicone probably wouldn't be bad.

On the other hand, it seems to me that the elasticity above and below the eyes is already not high enough – this will certainly not get better with thicker walls.

That's why I'm curious to see how the further tests go. In addition to other quantities of silicone, tests with other types of silicone are certainly worthwhile.

Basically, however, I am already very satisfied with these very first experiences of how to mold silicone.

Update (30.01.2024)

As promising as the first results were, I was not satisfied with the result after a few weeks. Above all, the lack of reproducibility despite the same amount of silicone and the same technology bothered me.

That's why I took a deeper look at the topic of "two-piece silicone molds" and gained my first experiences with it. These can be found here in a separate, newer article:

🔸 Multi-Piece Silicone Molds for Animatronic Dolls

Update (23.09.2023)

In the meantime, I have been able to gain further experience with different silicone materials and quantities, which I would like to briefly summarize here.

![]()

1. Attempt

| Topic | Info |

|---|---|

| Silicone | "Type 1 Duplicating Silicone Soft, Green" by Troll Factory |

| Quantity | 80ml |

| Color added | None |

| Technology | Swivel with robotic arm |

| Result | Skin quite thick, rather stiff and not very stretchy at the eyes |

![]()

2. Attempt

| Topic | Info |

|---|---|

| Silicone | "Type 1 Duplicating Silicone Soft, Green" by Troll Factory |

| Quantity | 60ml |

| Color added | None |

| Technology | Swivel with robotic arm |

| Result | Skin too thin, transparent, prone to tearing in thin areas |

![]()

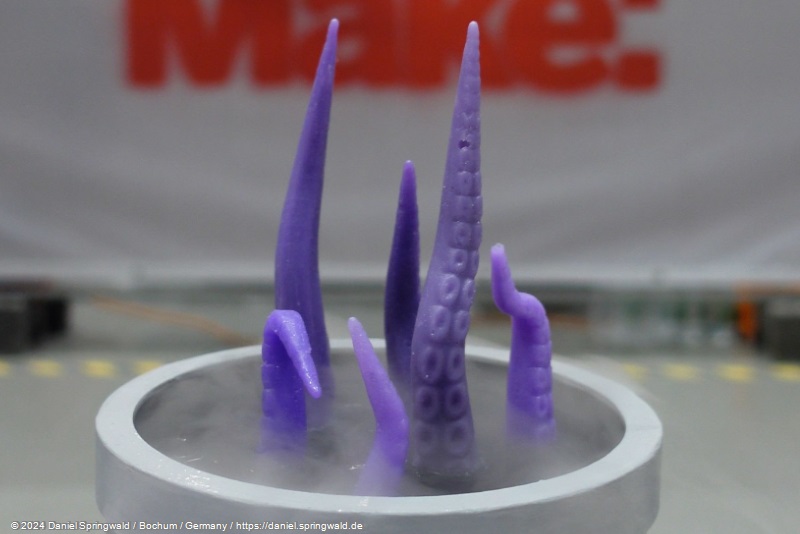

3. Attempt

| Topic | Info |

|---|---|

| Silicone | "Type 23 Duplicate Silicone Translucent" by Troll Factory |

| Quantity | 70ml |

| Color added | Drop Silicone Rubber Color 2 x white, 1 x yellow, 2 x green |

| Technology | Swivel with robotic arm |

| Result | Skin much too thin, transparent, very elastic, does not tear in thin areas |

![]()

4. Attempt

| Topic | Info |

|---|---|

| Silicone | "Type 23 Duplicate Silicone Translucent" by Troll Factory |

| Quantity | 100ml |

| Color added | Drop Silicone Rubber Color 2 x white, 1 x yellow, 2 x green |

| Technology | Swivel with robotic arm |

| Result | Skin thickness ok in many places, but very uneven and much too thick in others |

![]()

5. Attempt

Switching from robotic arm swivel to hand 😥 swivel

| Topic | Info |

|---|---|

| Silicone | "Type 1 Duplicating Silicone Soft, Green" by Troll Factory |

| Quantity | 40ml first layer, 40ml second layer |

| Color added | Drop Silicone Rubber Color 1 x white, 1 x yellow |

| Technology | Swivel by hand in two shifts |

| Result | Skin too thick, too stiff |

![]()

6. Attempt

| Topic | Info |

|---|---|

| Silicone | "Type 23 Duplicate Silicone Translucent" by Troll Factory |

| Quantity | 30ml first layer, 40ml second layer |

| Color added | Drop Silicone Rubber Color 2 x white, 1 x yellow, 1 x green |

| Technology | Swivel by hand in two shifts |

| Result | perfect thickness, very elastic, a little thin on the eyebrows - but ok |

![]()

Daniel

Daniel deutsche Version anzeigen

deutsche Version anzeigen